Coconut processing has emerged as a vital industry in many tropical regions, driven by the increasing global demand for coconut products. From coconut oil and milk to coir and sugar, the versatility of coconuts presents numerous opportunities for manufacturers. However, establishing a coconut factory requires careful planning and efficient construction solutions. Lida Group, a leader in prefabricated construction, offers comprehensive solutions tailored specifically for coconut factories. This article explores the benefits of coconut processing, the unique challenges faced by the industry, and how Lida Group addresses these challenges with innovative factory designs.

Understanding Coconut Processing

The Importance of Coconut Products

Coconuts are often referred to as the “tree of life” due to their wide range of uses. The various products derived from coconuts include:

- Coconut Oil: Used in cooking, cosmetics, and pharmaceuticals.

- Coconut Milk: A popular ingredient in many culinary traditions.

- Coconut Water: Valued for its hydration properties and health benefits.

- Coir: The fibrous husk used for making ropes, mats, and brushes.

- Coconut Sugar: A natural sweetener derived from the sap of the coconut tree.

The global market for these products has seen significant growth, prompting the need for efficient and well-structured coconut processing facilities.

The Coconut Processing Industry Landscape

The coconut processing industry faces several unique challenges, including:

- Quality Control: Maintaining the quality and freshness of coconut products is crucial for market competitiveness.

- Sustainability: With increasing scrutiny on environmental practices, manufacturers must adopt sustainable methods.

- Efficiency: As demand rises, factories must operate efficiently to meet production targets.

Benefits of Efficient Coconut Factory Design

1. Enhanced Production Efficiency

A well-designed coconut factory can significantly enhance production efficiency by:

- Streamlined Workflow: Optimized layouts can reduce unnecessary movement, allowing for smoother operations.

- Automated Processes: Incorporating automation can speed up production and reduce labor costs.

2. Cost-Effectiveness

Efficient factory designs lead to reduced operational costs:

- Lower Construction Costs: Prefabricated buildings reduce labor and material expenses.

- Operational Savings: Efficient designs minimize waste and reduce energy consumption.

3. Improved Quality Control

Quality control is essential in coconut processing:

- Dedicated Areas: Specific zones for sorting, processing, and packaging can help maintain product quality.

- Hygiene Standards: Well-structured factories can comply with health regulations, ensuring safe production processes.

4. Sustainability

Sustainable practices are increasingly important in modern manufacturing:

- Eco-Friendly Materials: Designing factories with sustainable materials can enhance a company’s green credentials.

- Waste Management: Efficient layouts can facilitate better waste management and recycling practices.

Lida Group’s Comprehensive Solutions

Who Is Lida Group?

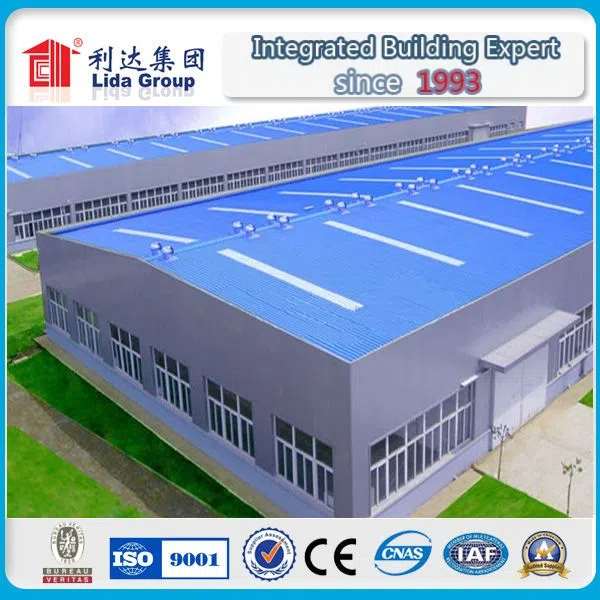

Lida Group is a prominent name in the prefabricated construction industry, specializing in designing and constructing facilities tailored to the unique needs of various sectors, including coconut processing. With a commitment to quality, innovation, and customer satisfaction, Lida Group has established itself as a trusted partner for businesses seeking efficient manufacturing solutions.

Key Innovations by Lida Group

1. Modular Construction Techniques

Lida Group employs modular construction techniques to enhance the efficiency and flexibility of coconut factory designs:

- Prefabricated Modules: Factories are built using prefabricated modules that can be easily transported and assembled on-site.

- Rapid Deployment: This approach allows for quick construction and minimal disruption to existing operations.

2. Advanced Technology Integration

Lida Group leverages advanced technologies to improve the design and functionality of coconut factories:

- Building Information Modeling (BIM): BIM technology enables precise planning and visualization, reducing errors during construction and enhancing collaboration among stakeholders.

- Smart Manufacturing Technologies: Integration of IoT devices allows for real-time monitoring of factory conditions, optimizing operations and maintenance schedules.

3. Customized Solutions

Recognizing that each coconut processing operation has unique requirements, Lida Group offers tailored solutions:

- Flexible Designs: Factories can be customized to accommodate various functions, such as processing, packaging, and storage.

- Client Collaboration: Lida Group works closely with clients to develop designs that align with their operational goals.

4. Sustainable Practices

Lida Group is committed to sustainability in its construction practices:

- Eco-Friendly Materials: The use of sustainable materials reduces environmental impact and promotes eco-friendly construction.

- Energy Management Systems: Factories are designed with energy-efficient systems that minimize energy consumption and reduce operational costs.

The Impact of Lida Group’s Solutions on Coconut Processing

1. Improving Workflow

Efficient workflow is crucial for productivity in coconut factories:

- Streamlined Layouts: Customizable designs allow businesses to implement workflows that minimize unnecessary movement and improve efficiency.

- Dedicated Work Areas: Incorporating specialized zones for different tasks enhances productivity and reduces downtime.

2. Enhancing Production Processes

Lida Group’s solutions can significantly enhance production processes in coconut factories:

- Optimized Production Lines: The ability to design production lines tailored to specific needs can reduce lead times and increase output.

- Quality Control Areas: Dedicated spaces for quality assurance help maintain high standards and reduce defects.

3. Supporting Training and Development

A well-designed factory can also facilitate employee training and development:

- Flexible Training Spaces: Factories can include areas specifically designed for training new employees on equipment and processes.

- Improved Collaboration: Open layouts can promote collaboration among teams, fostering innovation and problem-solving.

4. Supporting Scalability

As businesses grow, their operational needs may change, and Lida Group’s solutions can easily adapt:

- Expandable Designs: Modular factories can be expanded or modified without major disruptions, allowing businesses to scale operations efficiently.

- Future-Proofing: The modular nature of these factories enables businesses to future-proof their facilities against changing market demands.

Case Studies: Successful Implementation of Coconut Factories

Case Study 1: Coconut Oil Processing Plant

Challenge: A coconut oil manufacturer needed a new facility to increase production capacity while maintaining quality standards.

Solution: Lida Group designed and constructed a modular coconut oil processing plant featuring dedicated areas for extraction, filtration, and bottling.

Outcome: The new facility improved production efficiency by 30%, reduced lead times, and ensured compliance with health regulations.

Case Study 2: Coconut Water Bottling Facility

Challenge: A startup wanted to enter the coconut water market but required a facility that could handle high-volume production.

Solution: Lida Group developed a customized bottling facility with automated filling and packaging lines.

Outcome: The facility enabled the startup to scale operations rapidly, meeting market demand while maintaining product quality.

Case Study 3: Coir Manufacturing Plant

Challenge: A company specializing in coir products needed a new factory to expand its production capabilities.

Solution: Lida Group constructed a modular coir manufacturing plant that included spaces for processing, storage, and distribution.

Outcome: The new facility improved operational efficiency and allowed the company to increase its product offerings.

The Future of Coconut Processing with Lida Group

1. Emphasizing Sustainability

As environmental concerns grow, the coconut processing industry must prioritize sustainable practices:

- Green Certifications: More companies will seek certifications for sustainable manufacturing practices, demonstrating their commitment to environmental responsibility.

- Waste Reduction: Efficient factory designs can facilitate better waste management, ensuring that by-products are utilized or recycled.

2. Embracing Technology

The integration of advanced technologies will continue to shape the coconut processing industry:

- Automation: Automated systems for sorting, processing, and packaging will enhance efficiency and reduce labor costs.

- Data Analytics: Utilizing data analytics can improve decision-making and operational efficiency in coconut factories.

3. Meeting Global Demand

As the global demand for coconut products increases, manufacturers must be prepared to scale operations:

- Flexible Manufacturing: Lida Group’s modular solutions allow businesses to quickly adapt to changing market conditions.

- Local Production: Establishing factories closer to key markets can reduce transportation costs and lead times.

4. Enhancing Product Quality

Quality will remain a key focus in coconut processing:

- Hygiene Standards: Implementing stringent hygiene standards in factory design will ensure product safety and quality.

- Quality Control Systems: Incorporating effective quality control measures will help maintain high standards and reduce defects.

Conclusion

Lida Group’s comprehensive solutions for coconut factories are revolutionizing the way businesses approach coconut processing. By offering efficient, sustainable, and customizable designs, these solutions empower manufacturers to enhance productivity, meet growing market demands, and maintain high-quality standards.

As the coconut processing industry continues to evolve, Lida Group stands at the forefront of this transformation, providing innovative factory designs that support operational efficiency and sustainability. The journey toward a more efficient and responsible coconut processing future is just beginning, and Lida Group is leading the way in shaping this promising landscape. Through strategic investments and a focus on customer satisfaction, Lida Group is not only enhancing the capabilities of its clients but also contributing to the evolution of the coconut processing industry as a whole.

Contact Us

Post time: May-08-2025