In today’s rapidly evolving industrial landscape, the need for effective and efficient housing solutions for workers has become increasingly critical. Industries such as construction, mining, and oil and gas often require temporary accommodation for their workforce, especially in remote locations. Prefabricated (prefab) homes have emerged as a practical solution, providing comfortable, durable, and flexible living spaces tailored to the needs of labor camps. This article explores the benefits, design, construction processes, and future potential of prefab homes in enhancing living conditions in labor camps.

Understanding Prefab Homes

What Are Prefab Homes?

Prefab homes are buildings manufactured off-site in a controlled factory environment and then transported to their final location for assembly. This method contrasts with traditional construction, which typically involves extensive on-site labor and longer timelines. Prefab homes can include modular designs, panelized systems, or complete structures pre-assembled for quick deployment.

Key Features of Prefab Homes

- Speed of Construction: Prefab homes can be assembled much faster than traditional buildings, often within weeks.

- Quality Control: Factory production allows for stringent quality assurance, ensuring that all components meet high safety and performance standards.

- Cost-Effectiveness: The streamlined production process often results in lower labor and material costs, making prefab homes a budget-friendly option for labor accommodation.

- Sustainability: Many prefab homes are designed with eco-friendly materials and energy-efficient systems, promoting sustainable living practices.

Benefits of Prefab Homes in Labor Camps

1. Enhanced Living Conditions

Creating comfortable living environments is essential for worker satisfaction and productivity. Prefab homes can significantly improve living conditions:

- Modern Amenities: These homes can include kitchens, bathrooms, and communal areas, ensuring that workers have a comfortable place to live and socialize.

- Privacy: Individual units provide private sleeping quarters, allowing workers to relax after long shifts.

2. Improved Mental and Physical Health

A well-designed living space can have a profound impact on workers’ mental and physical health:

- Stress Reduction: Comfortable living environments can alleviate stress and contribute to overall well-being.

- Encouraging Healthy Lifestyles: Prefab homes can incorporate recreational facilities that promote physical activity and social interaction among workers.

3. Increased Productivity

Worker productivity is closely linked to their living conditions:

- Reduced Commute Times: By housing workers on-site, prefab homes minimize travel time, allowing for longer rest periods and greater focus on work tasks.

- Better Work-Life Balance: Comfortable living conditions contribute to a healthier work-life balance, enhancing job satisfaction and reducing turnover rates.

4. Cost Savings

Investing in prefab homes can lead to substantial cost savings for companies:

- Lower Construction Costs: The efficiency of factory production reduces both labor and material costs, making prefab homes a budget-friendly option for worker accommodation.

- Operational Savings: Improved worker satisfaction and reduced travel times can save companies money over time.

The Design and Construction Process

1. Planning and Needs Assessment

The foundation of successful prefab home projects begins with thorough planning:

- Understanding Workforce Needs: Assessing the specific requirements of the workforce, including the number of occupants and desired amenities, is crucial for effective design.

- Site Evaluation: Evaluating the site for accessibility, environmental conditions, and available resources helps inform the design process.

2. Modular Production

Once the design is finalized, the construction process begins off-site:

- Factory Production: Modular units are constructed in a controlled environment, allowing for precision and quality control. This typically involves assembling walls, roofs, and internal fixtures.

- Quality Assurance: Each unit undergoes rigorous inspections to ensure safety and quality standards are met before being transported to the site.

3. Transportation and Assembly

The next phase involves transporting the prefabricated units to the construction site:

- Logistics Management: Coordinating transportation logistics is essential to ensure that units arrive on time and in good condition.

- On-Site Assembly: Once on-site, the units can be quickly assembled into the desired configuration, often within a matter of days.

4. Final Touches

After assembly, the final steps include:

- Interior Finishing: Adding furnishings and appliances ensures that the prefab homes are ready for occupancy.

- Site Preparation: Ensuring that the surrounding area is safe and accessible for workers, including landscaping and utility connections.

Sustainability in Prefab Home Construction

1. Eco-Friendly Materials

Sustainability is a core principle in the design and construction of prefab homes:

- Recycled Materials: Utilizing recycled materials can significantly reduce the environmental impact of construction.

- Sustainable Sourcing: Ensuring that any additional materials used for modifications are sourced responsibly enhances the overall sustainability of the project.

2. Energy Efficiency

Prefab homes can be designed with energy efficiency in mind:

- High-Quality Insulation: Effective insulation helps regulate indoor temperatures, reducing energy consumption for heating and cooling.

- Renewable Energy Solutions: Incorporating solar panels or other renewable energy technologies can minimize reliance on fossil fuels and lower operational costs.

3. Waste Reduction

The prefabricated construction process inherently reduces waste:

- Controlled Environment: Building in a factory setting allows for better management of materials and minimizes waste compared to traditional construction sites.

- Recycling Programs: Implementing recycling initiatives for any waste generated during construction can further reduce environmental impact.

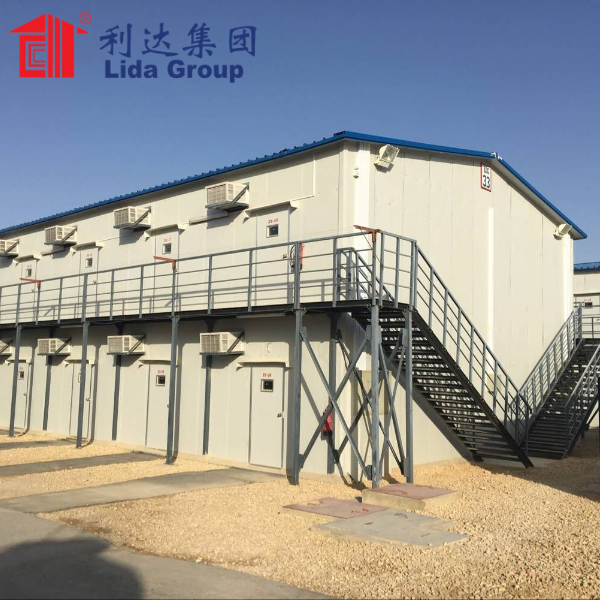

Applications of Prefab Homes in Labor Camps

1. Construction Sites

Prefab homes are widely used in the construction industry:

- Temporary Accommodation: They provide immediate housing solutions for workers involved in large-scale construction projects, such as highways, bridges, and buildings.

- On-Site Offices: In addition to living quarters, prefab homes can serve as office spaces for project managers and supervisors.

2. Mining Operations

In remote mining locations, prefab homes offer practical solutions:

- Comfortable Living Quarters: Workers can enjoy comfortable living conditions close to the site, reducing travel time and improving morale.

- Adaptable Spaces: As mining operations expand or shift, prefab homes can be easily relocated or expanded to accommodate changing needs.

3. Oil and Gas Operations

Industries such as oil and gas often require accommodation in remote locations:

- On-Site Housing: Prefab homes provide practical living solutions for workers stationed far from urban centers, allowing them to focus on their jobs without the burden of long commutes.

- Integrated Facilities: These structures can include recreational areas and communal spaces to promote community and well-being among workers.

4. Disaster Relief

Prefab homes are invaluable in disaster relief efforts:

- Rapid Deployment: After natural disasters, prefab homes can be quickly assembled to provide temporary housing for displaced individuals.

- Flexible Solutions: They can be customized to meet the specific needs of affected communities, ensuring that adequate shelter is available.

Case Studies: Successful Prefab Home Projects

Case Study 1: Worker Accommodation for Construction

Challenge: A major construction company needed a labor camp to accommodate workers on a large infrastructure project.

Solution: The company opted for prefab homes designed by a leading firm, featuring modular living units and communal facilities.

Outcome: The project was completed ahead of schedule, and worker satisfaction significantly improved, leading to increased productivity and reduced turnover rates.

Case Study 2: Mining Camp Development

Challenge: A mining company sought to establish a labor camp in a remote location to support its operations.

Solution: Prefab homes were developed with comfortable accommodations and dining facilities tailored for the needs of mining workers.

Outcome: The camp provided a supportive living environment, leading to increased worker morale and productivity.

Case Study 3: Disaster Relief Housing

Challenge: After a natural disaster, there was an urgent need for temporary housing for displaced individuals.

Solution: Prefab homes were rapidly deployed to provide shelter for affected families, with each unit designed to accommodate basic living needs.

Outcome: The quick deployment of prefab homes helped restore stability for displaced individuals and provided a safe living environment during recovery efforts.

The Future of Prefab Homes in Labor Camps

Trends Shaping the Industry

The future of prefab homes will be influenced by several key trends:

1. Increased Demand for Sustainable Practices

As environmental awareness grows, industries are under pressure to adopt sustainable practices:

- Eco-Friendly Solutions: Companies prioritizing sustainability will appeal to a growing market of environmentally conscious consumers.

- Regulatory Changes: Governments may implement stricter regulations on environmental impact, driving the need for sustainable prefab housing solutions.

2. Technological Advancements

Advancements in technology will enhance the efficiency of prefab homes:

- Smart Technologies: The integration of IoT devices will enable real-time monitoring and optimization of living conditions and resource usage.

- Automation: Automation in production processes can improve efficiency and reduce labor costs.

3. Customization and Modularity

The demand for customizable and modular designs will continue to grow:

- Flexible Accommodation Solutions: Businesses will increasingly require prefab homes that can be easily adapted to changing operational needs.

- Rapid Deployment: Prefabricated solutions will allow for quick construction and minimal disruption, catering to the fast-paced demands of modern industries.

Commitment to Innovation

Leading firms in the prefab housing market remain dedicated to innovation:

- Research and Development: Continuous investment in R&D ensures that companies stay at the forefront of technological advancements in prefab construction.

- Client Collaboration: By working closely with clients, firms can develop tailored solutions that meet specific operational requirements and sustainability goals.

Conclusion

Prefab homes represent a significant advancement in providing efficient and comfortable living solutions for labor camps. Their focus on modern amenities, durability, and sustainability makes them an ideal choice for various industries, from construction to mining and disaster relief.

As the demand for temporary and semi-permanent worker accommodation continues to grow, prefab homes will play a crucial role in enhancing living conditions and worker satisfaction. The future of prefab housing is promising, with the potential for innovation and improvement in living conditions for on-site workers.

In an era where flexibility and environmental responsibility are paramount, prefab homes provide an innovative solution to the challenges of worker accommodation. Through strategic investments and a commitment to excellence, the prefab housing sector is poised to enhance operational capabilities for its clients and contribute positively to the evolution of the construction industry. The journey toward a more efficient and sustainable future in workforce accommodation is just beginning, and the potential for innovation is limitless.

Contact Us

Post time: May-29-2025