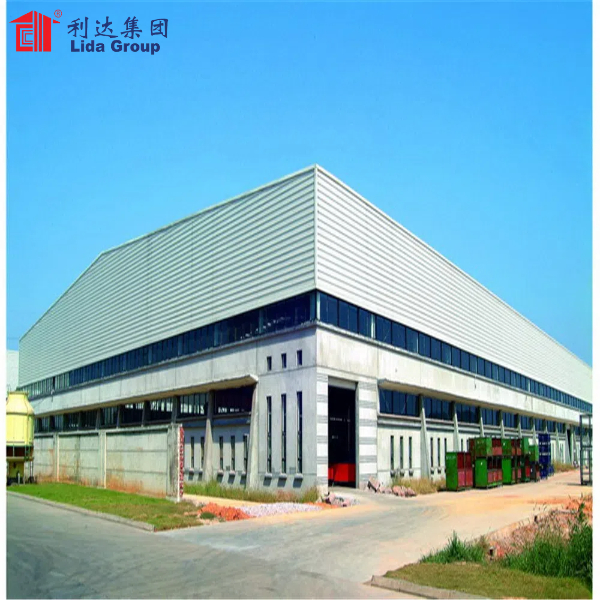

In today’s competitive industrial landscape, businesses are continually seeking ways to enhance efficiency, reduce costs, and improve operational performance. One of the most effective solutions available is the construction of steel structure workshops. These facilities offer a myriad of advantages, including durability, flexibility, and rapid construction timelines. Lida Group, a leader in the prefabricated construction industry, specializes in designing and constructing steel structure workshops tailored to meet the unique needs of various sectors. This article explores the benefits of steel structure workshops, the innovative solutions provided by Lida Group, and why investing in these structures is a smart choice for businesses.

Understanding Steel Structure Workshops

What Are Steel Structure Workshops?

Steel structure workshops are industrial buildings primarily constructed using a steel framework. This construction method is gaining popularity due to its numerous benefits, making it ideal for various applications, such as manufacturing, assembly, and storage. Key features of steel structure workshops include:

- Robust Frame: The steel frame provides exceptional strength and stability, allowing for larger spans and open spaces.

- Modular Design: Steel workshops can be designed in modules, facilitating easy expansion and reconfiguration.

- Quick Assembly: Prefabricated components can be manufactured off-site and assembled on-site, significantly reducing construction time.

Applications of Steel Structure Workshops

Steel structure workshops can be utilized across various sectors, including:

- Manufacturing: Ideal for production lines and assembly areas.

- Automotive: Serving as repair shops, showrooms, and parts storage.

- Warehousing: Providing space for inventory management and distribution.

- Agriculture: Acting as equipment storage and processing facilities.

Benefits of Steel Structure Workshops

1. Cost-Effectiveness

One of the primary advantages of steel structure workshops is their cost-effectiveness:

- Reduced Construction Costs: The prefabrication process minimizes labor requirements and material waste, leading to lower overall expenses.

- Long-Term Savings: Steel’s durability translates to lower maintenance and repair costs over time, providing significant long-term savings for businesses.

2. Speed of Construction

Steel structure workshops can be constructed much faster than traditional buildings:

- Rapid Assembly: Prefabricated components are produced off-site, allowing for quick on-site assembly and minimal downtime.

- Efficient Project Timelines: Businesses can begin operations sooner, which is particularly beneficial for projects with tight deadlines.

3. Design Flexibility

Steel workshops offer unparalleled design flexibility:

- Customizable Layouts: Workshops can be tailored to meet specific operational needs, allowing for efficient workflows and space utilization.

- Expandable Designs: As business needs change, steel workshops can be easily expanded or modified without significant disruption.

4. Enhanced Durability

Steel structure workshops are built to last:

- High-Quality Materials: Steel components are resistant to environmental factors, pests, and fire, ensuring longevity.

- Low Maintenance: Steel structures require less maintenance compared to traditional materials, resulting in long-term savings.

5. Sustainability

Sustainability is increasingly important in modern construction, and steel workshops contribute to eco-friendly practices:

- Recyclable Materials: Steel is 100% recyclable, making it an environmentally responsible choice for construction.

- Energy Efficiency: Steel workshops can incorporate energy-efficient designs and systems, reducing overall energy consumption.

Lida Group’s Innovative Solutions

Who Is Lida Group?

Lida Group is a prominent player in the prefabricated construction industry, specializing in designing and constructing steel structure workshops tailored to the unique needs of various sectors. With a commitment to quality, innovation, and customer satisfaction, Lida Group has established itself as a trusted partner for businesses seeking efficient workshop solutions.

Key Innovations by Lida Group

1. Modular Construction Techniques

Lida Group employs modular construction techniques to enhance the efficiency and flexibility of steel workshops:

- Prefabricated Modules: Workshops are built using prefabricated steel modules that can be easily transported and assembled on-site.

- Rapid Deployment: This approach allows for quick construction and minimal disruption to existing operations.

2. Advanced Technology Integration

Lida Group leverages advanced technologies to improve the design and functionality of steel structure workshops:

- Building Information Modeling (BIM): BIM technology enables precise planning and visualization, reducing errors during construction and enhancing collaboration among stakeholders.

- Smart Manufacturing Technologies: Integration of IoT devices allows for real-time monitoring of workshop conditions, optimizing operations and maintenance schedules.

3. Customized Solutions

Recognizing that each business has unique requirements, Lida Group offers tailored solutions to meet specific operational needs:

- Flexible Designs: Workshops can be customized to accommodate various functions, such as production, storage, and administrative areas.

- Client Collaboration: Lida Group works closely with clients to develop designs that align with their operational goals.

4. Sustainable Practices

Lida Group is committed to sustainability in its construction practices:

- Eco-Friendly Materials: The use of sustainable materials reduces environmental impact and promotes eco-friendly construction.

- Energy Management Systems: Workshops are designed with energy-efficient systems that minimize energy consumption and reduce operational costs.

The Impact of Steel Structure Workshops on Operational Efficiency

1. Improving Workflow

Efficient workflow is crucial for productivity, and steel structure workshops play a vital role in optimizing operations:

- Streamlined Layouts: Customizable designs allow businesses to implement workflows that minimize unnecessary movement and improve efficiency.

- Dedicated Work Areas: Incorporating specialized zones for different tasks enhances productivity and reduces downtime.

2. Enhancing Production Processes

Steel structure workshops can significantly enhance production processes:

- Optimized Production Lines: The ability to design production lines tailored to specific needs can reduce lead times and increase output.

- Quality Control Areas: Dedicated spaces for quality assurance help maintain high standards and reduce defects.

3. Facilitating Training and Development

A well-designed workshop can facilitate employee training and development:

- Flexible Training Spaces: Workshops can include areas specifically designed for training new employees on equipment and processes.

- Improved Collaboration: Open layouts can promote collaboration among teams, fostering innovation and problem-solving.

4. Supporting Scalability

As businesses grow, their operational needs may change, and steel structure workshops can easily adapt:

- Expandable Designs: Steel workshops can be expanded or modified without major disruptions, allowing businesses to scale operations efficiently.

- Future-Proofing: The modular nature of these workshops enables businesses to future-proof their facilities against changing market demands.

Case Studies: Successful Implementation of Steel Structure Workshops

Case Study 1: Automotive Repair Workshop

Challenge: An automotive repair shop needed a new facility to accommodate increased customer demand and improve service efficiency.

Solution: Lida Group designed and constructed a steel structure workshop that included multiple service bays and customer waiting areas.

Outcome: The new facility improved service efficiency by 40%, reduced wait times for customers, and enhanced overall customer satisfaction.

Case Study 2: Manufacturing Assembly Plant

Challenge: A manufacturing company required a workshop to streamline assembly processes and increase production capacity.

Solution: Lida Group developed a customized steel structure workshop with dedicated assembly lines and quality control zones.

Outcome: The facility improved production efficiency, reduced lead times, and allowed the company to scale operations to meet market demands.

Case Study 3: Agricultural Equipment Storage

Challenge: A farming operation needed a workshop to store equipment and provide maintenance services.

Solution: Lida Group constructed a spacious steel structure workshop with designated areas for storage, repair, and maintenance.

Outcome: The new facility enhanced equipment management, reduced downtime, and improved operational efficiency on the farm.

The Future of Steel Structure Workshops

Trends Shaping the Industry

The future of steel structure workshops will be influenced by several key trends:

1. Increased Automation

As technology continues to advance, automation in workshop operations is becoming increasingly important:

- Robotics: The use of robotic systems for tasks such as assembly and material handling will enhance efficiency and reduce labor costs.

- Smart Manufacturing: Technologies that enable real-time monitoring and control of production processes will optimize operations.

2. Sustainability Initiatives

As environmental concerns grow, the emphasis on sustainability in construction will continue to rise:

- Green Building Certifications: More companies will seek certifications for sustainable building practices, demonstrating their commitment to environmental responsibility.

- Energy-Efficient Designs: Future steel structure workshops will increasingly incorporate renewable energy solutions, such as solar panels, to reduce energy costs.

3. Customization and Modularity

The demand for customizable and modular designs will persist:

- Flexible Space Solutions: Businesses will increasingly require workshops that can be easily adapted to changing operational needs.

- Rapid Deployment: Prefabricated solutions will allow for quick construction and minimal disruption, catering to the fast-paced demands of modern manufacturing.

Lida Group’s Commitment to Innovation

Lida Group is dedicated to leading the charge in the development of steel structure workshops:

- Research and Development: Continuous investment in R&D ensures that Lida Group remains at the forefront of technological advancements in workshop construction.

- Client Collaboration: By working closely with clients, Lida Group can develop tailored workshop solutions that meet specific operational requirements and market demands.

Conclusion

Investing in steel structure workshops from Lida Group is a smart choice for businesses looking to enhance operational efficiency, reduce costs, and improve productivity. With their cost-effectiveness, speed of construction, design flexibility, and sustainability, these workshops provide a robust solution for various industrial applications.

As the demand for innovative workshop solutions continues to grow, Lida Group is well-positioned to provide cutting-edge designs that meet the evolving needs of various sectors. The future of workshop construction is bright, and Lida Group is at the forefront of this transformation, helping businesses optimize their operations and achieve their goals.

In an era where efficiency and sustainability are paramount, Lida Group’s commitment to excellence ensures that steel structure workshops will play a crucial role in shaping the future of industrial facilities. Through strategic investments and a focus on customer satisfaction, Lida Group is enhancing operational capabilities for its clients and contributing to the evolution of the construction industry as a whole. The journey toward a more efficient and sustainable future in workshop design is just beginning, and Lida Group is leading the way.

Contact Us

Post time: May-09-2025