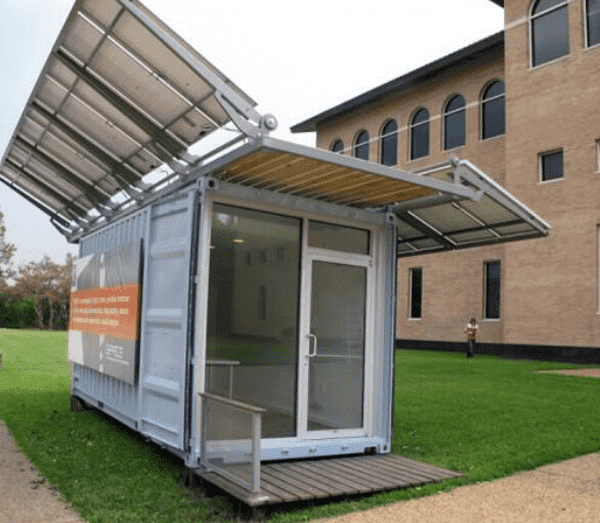

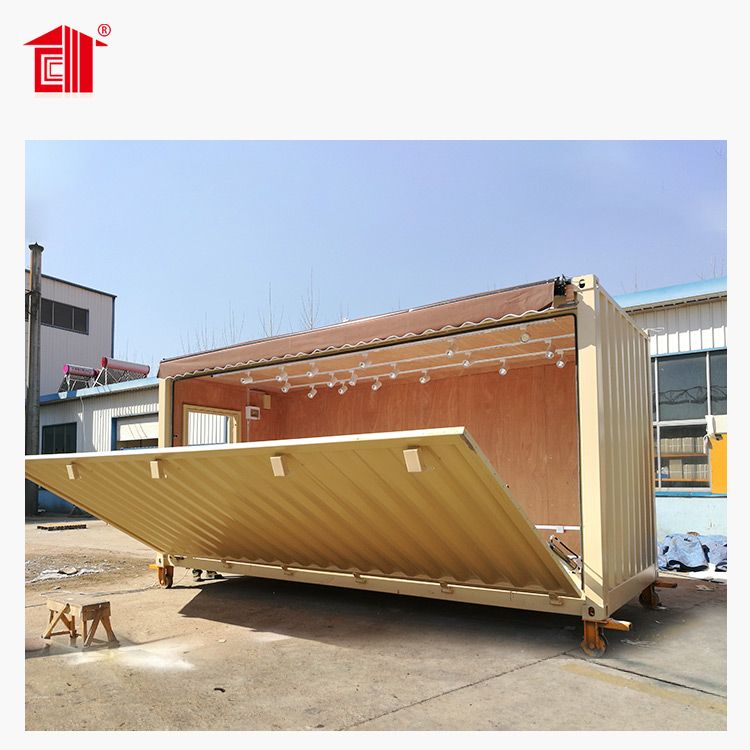

OEM Manufacturer Welding Container House - High Quality Luxury Assembled Container House Modern Prefab Modular Buildings Accommodation – Henglida

OEM Manufacturer Welding Container House - High Quality Luxury Assembled Container House Modern Prefab Modular Buildings Accommodation – Henglida Detail:

| Specification | 1) 20ft: 6055*2435*2896mm |

| 2) 40ft: 12192*2435*2896mm | |

| 3) Roof Type: Flat roof with organized internal water draining design | |

| 4) Storey: ≤3 | |

| Design parameter | 1) Life span: up to 20years |

| 2) Floor Live load: 2.0KN/m2 | |

| 3) Roof Live load: 0.5KN/m2 | |

| 4) Wind load: 0.6KN/m2 | |

| 5) Earthquake-resistance: Grade 8, Fire-proof: Grade 4 | |

| Wall panel | 1) Thickness: 75mm fiber glass sandwich panel, effective width: 1150mm |

| 2) Exterior steel sheet (standard configuration): Corrugated 0.4mm Aluminum-zinc color steel sheet, PE finishing coat, Color: white, Aluminum-zinc thickness≥40g/m2 | |

| 3) Insulation layer (standard configuration): 75mm Fiber glass, density≥50kg/m3, Fire-proof standard: grade A non-flambable | |

| 4) Interior steel sheet(standard configuration): Flat 0.4mm Aluminum-zinc color steel sheet, PE finishing coat, Color: white, Aluminum-Zinc thickness≥40g/m2 | |

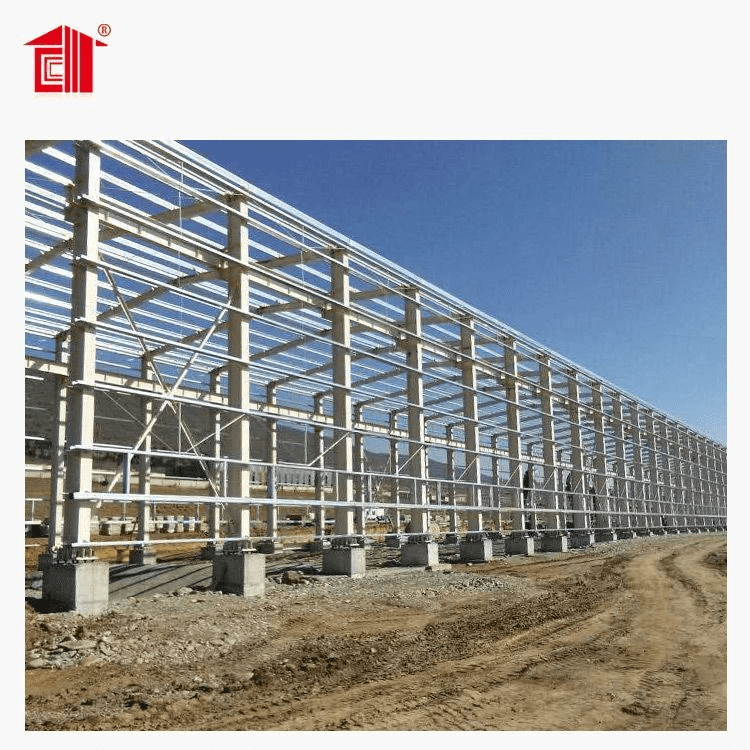

| Roof system | 1) Steel frame & accessories: Main roof frame: cold formed steel, thickness=2.5mm, galvanized. with 4pcs galvanized lifting corners. Roof purlin: C80*40*15*2.0, galvanized. Q235B steel |

| 2) Roof panel: 0.4 or 0.5mm thickness Aluminum-zinc color steel sheet, PE finishing coat. Color: white, Aluminum thickness≥70g/m2, 360° full connection | |

| 3) Insulation: 100mm thickness Fiber glass with aluminum foil, Density=14kg/m3, Grade A fire-proof, nonflammable. | |

| 4) Ceiling board: V-170 type, 0.5mm Aluminum-zinc color steel sheet, PE finishing coat. Color: white, Aluminum-zinc thickness≥40g/m2. | |

| 5) Industrial socket: Fixed in explosion-proof box at the top beam of the short side, with 1 main power plug for power connection between containers | |

| Corner pillar | 1) Cold rolled steel: 4pcs pillar with same dimension, thickness=3mm, steel grade Q235B. |

| 2) Corner pillar and main frame are joined by hexagon socket head bolt, strength: grade 8.8. Filled with Fiberglass insulation | |

| Floor System | 1) Steel structure & accessories: Main floor frame: cold formed steel, thickness 3.5mm, galvanization; Floor purlin:C120*40*15*2.0, galvanized. Q235B steel. Standard container is Without forklift hole, it can be added according to customer’s requirement. |

| 2) Insulation (optional): 100mm thickness Fiber glass with aluminum foil, Density=14kg/m3. Flammability: gradeA, nonflammable. | |

| 3) Bottom covering (optional): 0.25mm color steel sheet, Zinc thickness≥70g/m2. | |

| 4) Floor board: 18mm thickness fiber cement board, Fire-proof: gradeB1. Density≥1.3g/cm3 | |

| 5) Interior Flooring: 1.5mm thickness PVC leather, Blue marble color | |

| Door & Window | 1) Insulated light steel door: Entrance door is W850*H2030mm, Toilet door is W700*H2030mm. |

| 2) PVC sliding window, double glass 5mm thickness, with mosquito screen and security bar. Standard window: W800*H1100mm(for 2.4meter’s container), W1130*H1100mm(for 3 meter’s container), Toilet window: W800*H500mm | |

| Electric system | 1) Rated power: 5.0 KW, suggestion external power source ≤3 in series. |

| 2) Technical parameters: CEE industrial plug, socket voltage 220V- 250V, 2P32A, Fixed in explosion-proof box at the top beam of the short side, the electric cable in the roof is protected by PVC pipe with CE certification; Using IP44 standard power distribution box. | |

| 3) Electrical data: main power cable is 6 mm2, AC cable is 4 mm2, socket cable is 2.5 mm2, lighting & switch cable is 1.5 mm2. Five sockets, 1pc AC socket of 3holes 16A, 4pcs socket of 5holes 10A. 1pc single connection switch, 2pcs double tube LED light, 2*15W. | |

| Painting | 1) Primer painting: epoxy primer, Zinc color, thickness: 20 – 40 μm. |

| 2) Finishing paint: Polyurethane finishing coat, white color, thickness: 40-50 μm. Total paint film thickness≥80μm. Galvanized components, galvanized layer thickness≥10μm (≥80g/m2) |

Product detail pictures:

Related Product Guide:

Our primary goal is to offer our clients a serious and responsible business relationship, providing personalized attention to all of them for OEM Manufacturer Welding Container House - High Quality Luxury Assembled Container House Modern Prefab Modular Buildings Accommodation – Henglida , The product will supply to all over the world, such as: Algeria, UAE, Iceland, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.