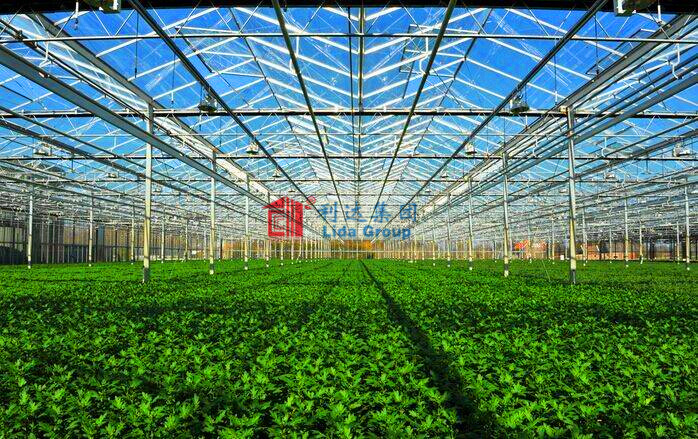

The vegetable greenhouse construction process is relatively simple and the technology is relatively fine. The supply of vegetables in China is mainly based on the cultivation of vegetable greenhouses. Therefore, the construction quality and design structure of vegetable greenhouses directly affect the yield and quality of vegetables in China.

1. Theme design: It is mainly to set the length, width and height of the vegetable greenhouse, and design according to the planted area. China’s ordinary greenhouse is about 120 square meters.

2. Optional materials: Vegetable greenhouse construction is divided into column type and steel frame type. All the steel frames used in the steel frame type are welded and only need to be built and reinforced for the foundation. The column-shaped vegetable greenhouse should be made of cement columns or bamboo. The steel frame shed has a long service life and can be used for up to 25 years. The column-shaped vegetable greenhouse can be used for 3-5 years.

3. Base construction: The vegetable greenhouse with vertical column type should be constructed with a weighing wall, and the width of the wall should be no less than 50 cm. And set a dedicated vent.

4. Arching: The vegetable greenhouses with steel frame do not need to be arched, and the bamboo rafts or the column-shaped vegetable greenhouses should be erected. To set up a uniform bamboo pole with a diameter of more than 2 cm, insert the big bamboo head into the back wall and fix the ends. Keep the arches consistent and the height balance is consistent. The column is supported at the highest point of the arch.

5. Plastic film laying: It is necessary to use a light-transparent plastic film for laying, with no drop film or purple light as the primary choice. Deep plastic burial is required on both sides of the greenhouse. The buried thickness is not less than 20 cm.

One: the scaffolding surface is smooth, the shed film is not easy to damage, and the service life of the shed film is prolonged.

Second: transportation and installation is convenient, through the bending machine, the height of the shed, the curvature, the shoulder height, the angle can be bent freely.

Three: vegetable greenhouse construction of the canopy tube at both ends of the rubber and plastic plug, sealed with adhesive, completely covering the metal surface, so that the underground part will never rust.

Four: There is no need for pillars in the middle of the scaffold, which greatly increases the area of cultivation, saves labor, and can be mechanically operated to increase work efficiency.

Five: The investment is small, the scale of the factory can be large or small, the factory can be 200 square meters, and the raw materials are above the county level.

Six: The production efficiency is high. According to the span of the vegetable greenhouse construction shed, the wall thickness can be adjusted arbitrarily, and the three people can produce 6000 meters in a single shift.

Seven: The cost is low, according to the span of the shed, small and small steel pipe specifications.

Eight: Recyclable and recyclable, one-third of the investment can be recovered.

Post time: Jun-27-2023